| |

|

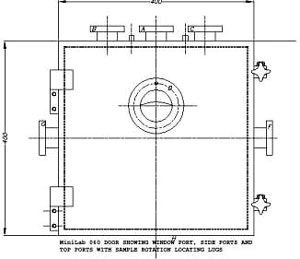

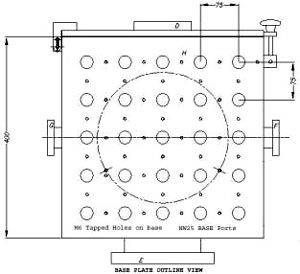

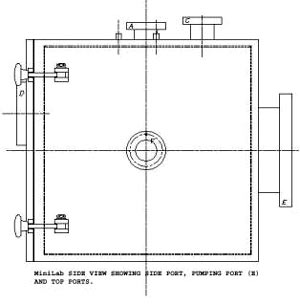

| The MiniLab 060 is a new concept in vacuum deposition. Created by an experienced team of designers with a background in UHV deposition technology, the Minilab 060 is a fully integrated mini box coater that achieves professional results. Problems associated with cramped multi-technique box coater systems have been overcome and miniaturised. Because MiniLab was designed as a multi-technique system from the start, it is able to adapt to configurations that many larger coating units find impossible to attain. The chamber is a development of Moorfields popular MINIBOX E306 retrofit. All stainless steel construction, it has twenty five one inch base ports to facilitate rapid customisation and flexibility of source and accessory positions. Two NW70CF wall ports provide options for front side sample heating, fast action shutter, thin film head, gas admission and optical access to the sample. Three NW70CF top ports provide options for sample rotation / positioning, sample heating, thermocouple and sample bias. The door window port has visual sample and source access with optional window shutter. The large rear NW200CF port ensures good conductivity for fast pump down. The MiniLab can be configured for true multi-technique, multi-layer deposition processes making it ideal for small scale production and R&D prototyping. A fully loaded system would, for example, include the following techniques: a 4 pocket E-Beam source with water cooling, HT and rotation device; a 4 filament thermal source with high current feed throughs with discrete filament selection; a TORUS "flexihead" magnetron for sputtering, a thin film monitor / controller; a variable speed rotary sample plate; back side graphite sample heating (to 1200°C) or quartz lamp heating ( front or back); plasma cleaning/ dry etch option; box shielding; sample shutter. With the maximum sample size a whopping 370mm o/d MiniLab competes with major OEM system designs but at a fraction of the price. Sample change is rapid due to the simple quick release sample plate and boss arrangement. Standard pumping is by way of a 500 l/sec turbo molecular pump and dual stage rotary mechanical backing, roughing pump. An additional cryo panel can be mounted in front of the turbo if high gas loads are experienced. Other pumping options are available. Vacuum control is one button start / vent, catered for by an onboard PLC which can update the system control menu with real-time status. Utilising the latest film monitor and control systems, the user is able to set multi-layer runs and control each step of the process and data log events for off line post analysis. The control system is supplied with off line software for setting up of film runs without the need to suffer down time. Most importantly, the Minilab 060 is cost effective. The modular design concept allows for retrofit additions as and when the budget allows. The Minilab chamber readily accepts components from OEMs so the user is not forced into expensive proprietary purchases | |

MiniLab 060 outline chamber drawings   |

Technical Specification Chamber Material:all stainless steel 316 Options from pumped box with control: EBE-4: Four hearth rotatable turret electron beam source, water cooled, 5kV / 600mA max emission TE-4: Thermal evaporator. All UHV construction, four hearth/ filament. 90A selectable PSU. TORUS: Flexi-head magnatron source. DC and RF compatible ARDK-8: Automated sample rotation kit variable speed motor, gearbox, controller, 10 - 60rpm, Sample plate and boss. PC-BAR: Plasma cleaning bar, feed throughs, power supply unit with variable 2000 vdc output, timer and emission control. ME10: Mini e-beam evaporator for refractory metal wire samples - locates on side port. Cheapest e-beam retrofit on the market! AS3000V: Small area dry etch / sample cleaning ion source. Variable 200eV - 3000eV beam energy. BOC6: Sample heater controller, digital timer, TC and set point, low hysterysis. 2 Zone, 4 outputs |